"We use PVDF Alucosmith for Architecture wall cladding"

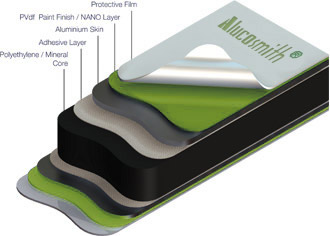

Nanometer Alucosmith® Aluminum Composite Panel

Alucosmith® nanometer Aluminum Composite Panel uses of high-tech nanometer-coating technology which makes the aluminum compsoite panel has much performance superior to the traditional polyester and PVDF panel. With the self-cleaning function, Nanometer Alucosmith® can always keep clean without any cleaning work. It always looks like new building wall even after 10 years application. Nanometer Alucosmith® aluminum composite panels are mainly applied to the high-grade building walls, star-rated hotels, convention centers, aireports, gas stations..... Especially in the area in serious air pollution.

Features of Nanometer Alucosmith®:

1) Anti-dirty

2) Anti-graffiti

3) Anti-scald

4) Self-cleaning

The dirt will not be easily attached to the surface because of the compact nanometer coating. The dirt would automatically break down under the ultraviolet.

Fire-Resistant (FR) Alucosmith® Aluminum Composite Panel

Panel Performance: conforms to Standard GB/T17748-1999

FR Conforms to:| Country | Standard | Grade |

| China | GB 8624 | B-s1,d0,t0 |

| Europe | EN13501 | B-s1,d0 |

| U.S.A | ASTM E84 | A |

| U.K. | BS 476 | 0、1 |

Class A (FR) Alucosmith® Aluminum Composite Panel technical data:

| No |

Test Item |

Test Methods |

B Grade Index |

Test Value |

Result |

|

| 1 | FIGRA(FIGRA),W/s | GB/T20284-2006 | B |

≤120 |

3 | Passed |

| 2 | THR600s(THR600s),m | GB/T20284-2006 | ≤7.5 | 0.4 | ||

| 3 | LFS,m | GB/T20284-2006 | <Sample Size | Conform | ||

| 4 | Fs,㎜ | GB/T8626-88 | ≤150 | 0 | ||

| 5 | SMOGRA,㎡/s2 | GB/T20284-2006 | s1 | ≤30 | 0 | Passed |

| 6 | TSP600s,㎡ | GB/T20284-2006 | ≤50 | 35 | ||

| 7 | Burning Drop | GB/T20284-2006 | d0 | 600s?No drop | Conform | Passed |

| 8 | Filter Paper Burn or Not | GB/T8626-88 | Filter Paper No Burn | Conform | ||

| 9 | Smoke Toxicity ,Grade | GB/T20285-2006 | t0 | Conform to ZA1 | ZA1 | / |

| 10 | Core Heating Value,MJ/kg | GB/T14402-93 | / | 11.7 | ||

| AL Heating Value,MJ/kg | GB/T14402-93 | 0 | ||||

| Coating Heating Value,MJ/㎡ | GB/T14402-93 | 0.4 | ||||

| Panel Heating Value,MJ/kg | GB/T14402-93 | 5.8 | ||||

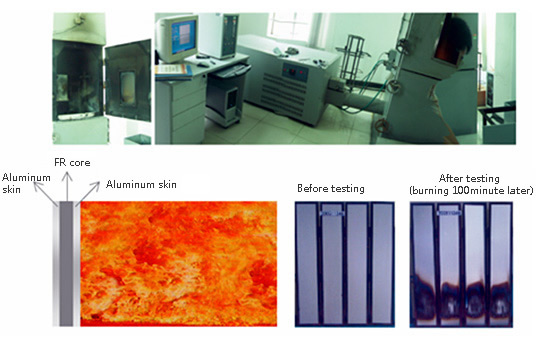

Fire-Resistant (FR) Alucosmith® Aluminum Composite Panel Test:

Burning Contrast Test:

Alucosmith High FR Grade(A2*) ACP Reputation

Standard Colour Range

Solid Color

| Milky White | High-Gloss Supper White | White | |||

| Light Yellow | Soft Green | Soft Blue | |||

| Lemon | Peak Green | Sea Blue | |||

| Orange | Dark Green | Dark Blue | |||

| China Red | Grey | Black | |||

Metallic Color

| Pearl White | Metallic Silver | Bright Silver | |||

| Champagne Silver | Bright Golden | Gold | |||

FEVE Finish

| AS-V002A-FEVE | AS-V006A-FEVE | AS-V011A-FEVE | |||

| AS-V012A-FEVE | AS-V015A-FEVE | AS-V001A-FEVE | |||

Special Finish

| Mirror Silver | Mirror Gold | Nano Bronze Metallic | |||

| Antique Copper | Brushed Copper | Brushed Silver | |||

Special Color

| AS-3701 Dreamax | AS-3703 Dreamax | AS-3705 Dreamax | |||

| Wild Cherry | Mahogany | Black Satin | |||

Alucosmith® can also be colour matched to almost any RAL colour - allowing corporate colours to be matched with ease.

Technical Specifications

| Testing item | Standard | Result |

| Unit weight | ASTM D792 | t3mm=4.6kg/m² t4mm=5.5kg/m² |

| outdoor temperature resistance | ASTM D1654 | No abnormity |

| Thermal expansion | ASTM D696 | 3.0x10-5°C-1 |

| Thermal deformation temperature | ASTM D648 | 115°C-1 |

| Thermal conduction | ASTM 976 | 0.102kcal/m.hr°C |

| Flexural rigidity | ASTM C393 | 14.0x105 |

| Impact resistance | ASTM D732 | 1.650kgf |

| Adhesive strength | ASTM D903 | 0.74kgf/mm |

| Sound-insulating rate | ASTM E413 | 29 |

| Flexural Elasticity | ASTM D790 | 4055kg/mm² |

| Shear resistance | ASTM D732 | 2.6kgf/mm² |

| Minimum bending radius | ASTM D790 | (LO)45mm(PO)70mm |

| Fire propagation | ASTM E84 | Qualified |

| Smoke developed | ASTM E84 | <45 |

| Wind-pressure resistance | ASTM E330 | Passed |

| Properties against water | ASTM E331 | Passed |

| Properties against air | ASTM E283 | Passed |

| Testing item | Standard | Result |

| Finish coat thickness | ISO 2360 (CNS 8406) | 27.6um |

| Gloss | ASTM D532-89 | 20-45% |

| Pencil hardness | ASTM D3363-00 | 2H |

| Toughness | ASTM D4145-83 | 2T no rift |

| Adhesice force | ASTM 3359-97 | 4B |

| Impact resistance | ASTM D2794-93 | >100kg.cm |

| Abrasion resistance | ASTM D968-93 | 64.6L/mil |

| Mortar resistance | ASTM 605.2-91 | 24hrs No blister |

| Humidity resistance | ASTM D714-97 | 3000hrs No blister |

| ASTM D2247-02 | ||

| Boiling-water resistance | ASTM D3359-B | Passed |

| Salt-spray resistance | ASTM B117-03 | 3000hrs No blister |

| Acid resistance | ASTM D1308-87 | No effect |

| AAMA 605.2-91, TEST#7, 7.31 | ||

| Alkail resistance | ASTM D1308-87 | Passed |

| Solvent resistance | ASTM D2248-73 | Passed |

| ECCA T5&NCCA NO.11-18 | ||

| Color retention | ASTM D2244-93 | ▲E=0.34 |

| Chalk resistance | ASTM D4214-98 | No Chalking |

| Gloss retention | ASTM D2244-93 | 84.2% |